Planet

Climate change and pollution

Decarbonising our shipping services

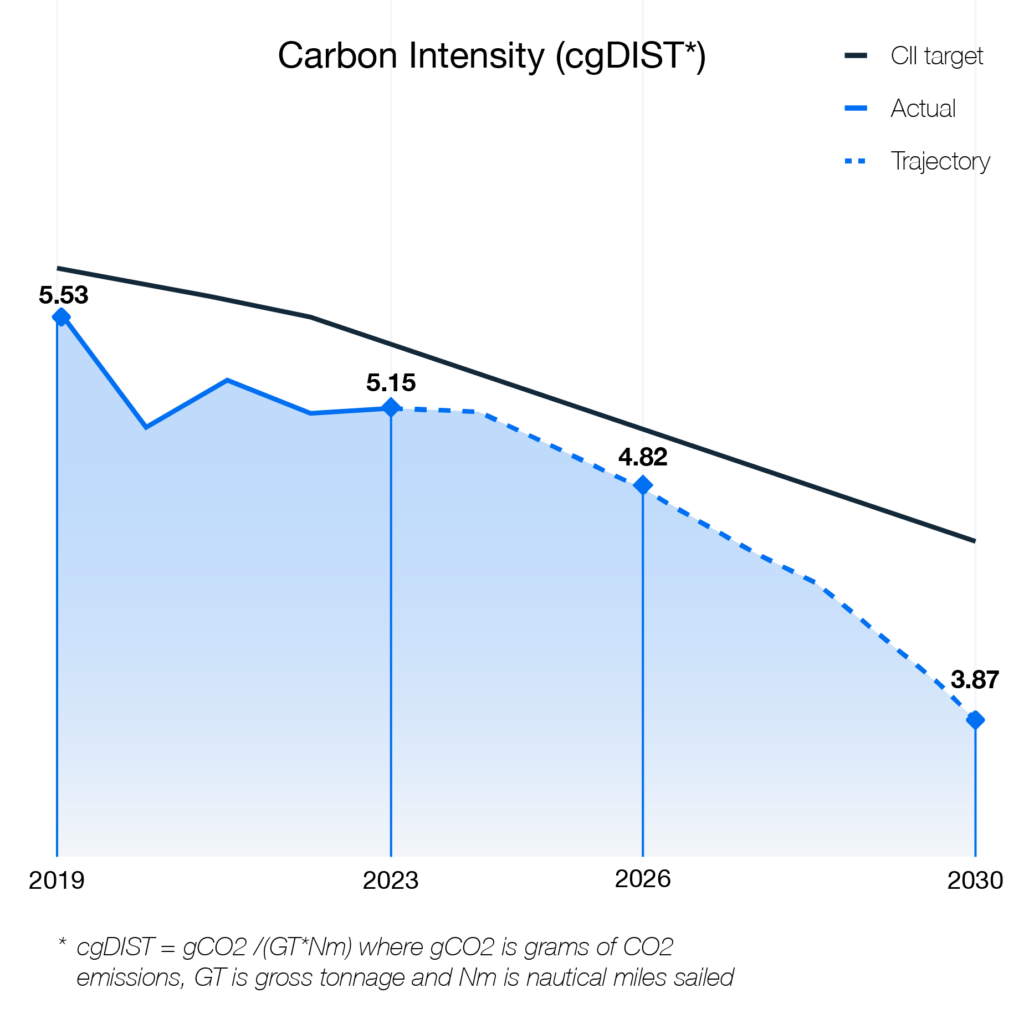

Höegh Autoliners is operating within a sector contributing significantly to global CO2 emissions. The sector is important for the global economy but is also among the hardest to abate when it comes to GHG emissions. We are having two clear targets for the decarbonisation of our own operations. The first target is to reduce our fleet carbon intensity by more than 30 percent by 2030 from a 2019 level. The second target is to become net zero by 2040. To meet the targets, Höegh Autoliners play an active role in bringing public authorities, customers, and suppliers together to work towards a future of zero-carbon shipping. We call for a level playing field, including appropriate carbon taxes and mechanisms that offset the current cost disadvantage of decarbonisation (e.g., contract for differences), incentivising the uptake of alternative fuels until it becomes a commercially viable choice.

The two focus areas when it comes to decarbonising our shipping operations are energy efficiency improvements on our existing fleet, and fleet transition including the uptake of alternative fuels.

Energy efficiency improvements (existing fleet)

We are continuously working with our long-term efforts to improve our energy efficiency, and 2023 has been a year where we have followed up on our commitment. We have ordered technical upgrades for 12 of our vessels, including new and enhanced propellers, propeller boss cap fins (PBCFs) and turbo charger deratings. These investments to our existing fleet, combined with optimising our operational performance are expected to enhance our energy efficiency and reduce our emissions. We also ordered cargo deck LED lights for 30 vessels to reduce overall energy consumption.

We experience an increased interest for biofuel from our customers, and in 2023, we have taken a record high delivery of around 10 380 MT of ISCC certified sustainable biofuel (B100), more than doubling our 2022 volumes. As we are expecting a continuous interest in biofuel going forward, we have partnered with the leading global provider of biofuels, VARO, for the supply of advanced biofuels for deep-sea transportation from Europe which is expected to continue during 2024.

Energy efficiency improvements won’t decarbonise shipping operations alone but combined with a transition of our fleet and adaptation of alternative fuels, our decarbonisation targets are achievable. We will continue to explore new and innovative ways to optimise our current fleet’s energy efficiency, and to further reduce our own and our customers’ environmental footprint.

Fleet transition and alternative fuels (fleet of the future)

Reaching our net-zero target by 2040 implies a significant transition of our fleet, including additions of zero-carbon ready vessels and disposal of legacy tonnage. In 2023, we exercised the option to build additional four multi-fuel and net zero carbon-ready Aurora class vessels (vessel 9-12). This move brings the newbuilding program, in which we have invested/committed about USD 1.3 billion, to twelve vessels, each with a capacity of 9 100 car equivalent units (CEU). The vessels are scheduled to be delivered between Q3 2024 and Q2 2027. This program will continue to make significant progress along with construction milestones that is well ahead of the original schedule. The first class-approved LNG/Ammonia tank was installed on our first Aurora vessel in Q4 2023, marking a significant milestone. The first two vessels are scheduled to be delivered in Q3 2024, and the vessels will be the largest and most carbon-efficient car carriers ever built.

We consider to launch vessel 9-12 as dual-fuel (Ammonia/MGO) vessels capable of running on Ammonia straight from the yard. As one of a few global shipping companies, Höegh Autoliners has secured access to four of the first 2-stroke ammonia engines produced and delivered in cooperation between MAN Energy Solutions and Hyundai Heavy Industries. This is a significant milestone on our path to zero.

In 2023, we also took the opportunity to optimise our asset portfolio in preparation of the first Aurora delivery, where we sold one older vessel that was delivered to her new owners in Q4 2023. Going forward, we will actively look for further opportunities that supports our decarbonisation journey.

Carbon intensity performance 2023

Despite congestion and tough operational conditions our efforts in managing carbon intensity showed resilience. The carbon intensity, measured as "capacity gross ton distance (cgDIST)", ended up at 5,15 for the year 2023. This means that we have achieved a carbon intensity reduction of about 38% from a 2008 level – close to IMO’s GHG strategy target of reducing carbon intensity of international shipping by at least 40% by 2030, with the same baseline. This is a result of systematic work with emissions reductions and fleet improvements for more than a decade, resulting in substantial carbon savings and emissions cuts. Further, our fleet is compliant with IMO’s current CII, EEXI and EEDI requirements, with about 80% of our vessels achieving IMO’s CII ratings of C or higher. The current fleet carbon intensity and its target trajectory are well below the calculated CII trajectory for our fleet in accordance with IMO’s CII regulations.

The Company has already taken significant steps towards its decarbonisation targets, and going forward we expect to gain further momentum through our ongoing fleet renewal. We believe that our coming Aurora vessels, together with phasing out legacy tonnage, and modification to existing fleet, will contribute to further carbon intensity improvements over the coming years.

Note: Höegh Autoliners has replaced the term Annual Efficiency Ratio (AER) with Capacity gross ton distance (cgDIST) for its carbon intensity measure, aligning with the Poseidon Principles. The change of terminology doesn’t affect past or future numbers, as the calculation method remains unchanged.

30 by 30 pathway

Fleet carbon intensity (cgDIST)

The reductions of the fleet carbon intensity over the past years show us that the initiatives we have implemented are working, and will help us reach our target of reducing carbon intensity by more than 30% by 2030, from a 2019 level. Aside from the expected effects from additional modifications on our existing fleet, we will over the coming years see larger effects from our green fleet renewal, including the phase-out of our legacy tonnage. Decarbonisation initiatives with their corresponding estimated carbon intensity reductions, are visualised below (future reductions are approximations)

The decarbonisation journey towards our 2030 and 2040 targets are highly dependent on the availability and the cost of alternative fuels. As we consider to launch our first ammonia-capable vessel in 2027, we are doing what we can to ensure availability of clean ammonia.

During the year, we have partnered with several ammonia suppliers for the supply and delivery of clean ammonia for our Aurora vessels. Until ammonia becomes available, we will continue to offer biofuel to our customers on a regular basis. We acknowledge that biofuel is unlikely to become the long-term solution for decarbonising shipping, however we view it as an important transition fuel until the technology and infrastructure makes alternative fuels available.

Our roadmap to net-zero

Partners on our Path to Zero

As a patron of the United Nations Global Compact (UNGC) we support the UN’s 10 principles and 17 Sustainable Development Goals (SDG). We are committed to conducting business in a safe, responsible and transparent manner, and we have incorporated this into how we work and behave.

Höegh Autoliners has joined the First Movers Coalition (FMC) as one of few shipping companies to send a strong market demand signal for the emerging technologies essential for a net-zero transition. Höegh Autoliners has committed to running at least 5% of our deep sea operations on either green ammonia or green methanol by 2030. Led by the World Economic Forum and the US Government, the First Movers Coalition targets hard-to-abate sectors including aluminium, aviation, chemicals, concrete, shipping, steel, and trucking, responsible for 30% of global emissions.

The Getting to Zero Coalition is a powerful alliance of more than 200 organisations (including 160 companies) within the maritime, energy, infrastructure and finance sectors, supported by key governments and IGOs. The Coalition is committed to getting commercially viable deep sea zero-emission vessels powered by zero-emission fuels into operation by 2030 towards full decarbonisation by 2050 – maritime shipping’s moon-shot ambition.

Miljøstiftelsen ZERO collaborates with companies in the maritime industry that are willing to lead the way by building zero-carbon vessels. ZERO works together with Höegh Autoliners on how to establish the frameworks needed to make those investments that contribute to enabling emission free international shipping. This includes the transition into alternative fuels, as well as regulatory conditions that make Norway attractive for such transitions.

We have joined Marine CleanTech, a maritime commercial partnership working to develop energy-efficient and sustainable technologies for the maritime sector. This partnership will accelerate the shift towards a sustainable future by creating possibilities for collaboration with organisations that share our vision and leveraging cutting-edge green technologies.

We have formalised an agreement with Kongsberg Digital to digitalise our fleet. This ensures installation of cutting-edge technology across nearly our entire fleet, including our 12 upcoming Aurora Class newbuildings. This is a strategic move that substantiates our commitment to leveraging digital solutions for increased efficiency and sustainability in the maritime industry.

We have formalised several LOIs with partners related to the supply and delivery of clean ammonia as a next generation sustainable maritime fuel for Höegh Autoliners’ Aurora class vessels.

We have entered into strategic partnership with the leading global provider of ocean transportation solutions, VARO, aimed at advancing the decarbonisation of maritime sectors. The collaboration with VARO focuses on supplying 100% advanced biofuels for deep-sea transportation from Europe and marks another significant step in reducing our environmental footprint.

Höegh Autoliners’ GHG emissions and pollution reporting

The emissions from consumption of fuel and refrigerants onboard our vessels are the sources to our scope 1 emissions. We are calculating the CO2 equivalents in accordance with the Greenhouse Gas Protocol and amounts to a total of 1 103 090 MT of CO2e.

Scope 2 emissions mainly consist of emissions from sourced electricity used for our local offices. We do report both location based and market based scope 2 emissions, of 324 MT of CO2e and 590 MT of CO2e respectively.

Höegh is for the first time presenting a complete scope 3 inventory, covering all categories assessed to be relevant. Previously, only category 3 (fuel and energy related activities not included in scope 1 and scope 2) and category 6 (business travel) was reported. That means that this year’s scope 3 emissions are not directly comparable with the prior year’s reporting for all categories. For category 1 and category 2, we have calculated and presented comparable figures for 2022.

For details on how our emissions are calculated, please refer to our methodology statement presented as a separate appendix to this annual report.

| GHG emissions in MT CO2e | 2023 | 2022 | 2021 |

|---|---|---|---|

| Scope 1 – Direct GHG emissions | 1 103 090 | 1 198 413 | 1 331 340 |

| Scope 2 – Location-based | 324 | 324 | 276 |

| Scope 2 – Market-based | 590 | 511 | 486 |

| Scope 3 – Category 1 (Purchased goods and services) | 94 622 | 94 521 | - |

| Scope 3 – Category 2 (Capital goods) | 34 815 | 32 932 | - |

| Scope 3 – Category 3 (Fuel- and energy-related activities not included in Scope 1 or Scope 2) | 198 374 | 210 526 | 230 029 |

| Scope 3 – Category 5 (Waste generated in Operations) | 584 | - | - |

| Scope 3 – Category 6 (Business travel) | 2 661 | 3 549 | 3 300 |

| Scope 3 – Category 7 (Employee commuting) | 289 | - | - |

| Total GHG emissions (Scope 1, 2 - location-based and 3) | 1 434 759 | 1 540 232 | 1 564 945 |

| Total GHG emissions (Scope 1, 2 - market-based and 3) | 1 435 025 | 1 540 419 | 1 565 155 |

| Biogenic emissions (From biofuel combustion) | 27 617 | 12 189 | 733 |

Höegh Autoliners only uses fuels that are compliant with IMO Global Sulphur Cap, 2020. We have decided to not install any scrubbers onboard our vessels and we are not planning to do so going forward. Installing and using scrubbers will likely increase fuel consumption as it requires additional auxiliary power.

Sewage treatment plant (STP) is installed in our vessels and adheres to MARPOL Guidelines Annex IV which provides the set of regulation regarding the proper sewage discharge of ships in marine waters. As stated in the guideline, ships are allowed to discharge treated and disinfected sewage to the sea when at least 12 nautical miles from the nearest land, with a speed of no less than 4 knots.

A company policy is also in place regarding sewage disposal to ensure compliance of the guidelines. In making sure that all vessel discharges are treated, each STP is approved by the “Class Society” and verified annually to ensure all vessels are complying with the regulations.

In 2023, the total amount of energy consumed was 15 157 GJ. Out of this, 2% was consumed from biofuel (8 741 MT) which is a significant increase compared to our 2022 consumption of 3 858 MT, with the rest coming from fossil fuels in 2023. We are taking delivery of two dual-fuel zero-carbon ready Aurora class vessels in second half of 2024 and expect to introduce LNG into our fuel mix for 2024 and onwards. Bio-LNG will also be considered.

During the year, we have formalised several LOIs with partners related to the supply and delivery of clean ammonia as a next generation sustainable maritime fuel for Höegh Autoliners’ Aurora class vessels. We expect ammonia to be part of the energy mix during by 2027.

| Other emissions to air (MT) | 2023 | 2022 | 2021 |

|---|---|---|---|

| Nitrogen Oxides (NOx) | 28 200 | 30 524 | 33 695 |

| Sulphur Oxides (SOx) | 2 844 | 3 072 | 3 405 |

| Particular Matter (PM) | 2 384 | 2 567 | 2 847 |

| Volatile Organic Compounts (VOC) | 1 101 | 1 182 | 1 304 |

| Carbon Monoxide (CO) | 1 010 | 1 084 | 1 194 |

| Black Carbon (BC) | 98 | 105 | 115 |

Biodiversity and ecosystems

Preventing introduction of invasive alien species

One of the major challenges in marine environment is introduction of invasive species which Höegh Autoliners takes seriously. Our commitment of being at the forefront in environmental protection at sea is related to adapting and implementing necessary actions to avoid instances where these species are carried either in the vessel’s ballast water or vessel’s hull. To prevent invasion of unwanted guests, Höegh Autoliners takes necessary steps through compliant and effective Ballast Water Treatment System (BWTS) and Anti-fouling system. BWTS is installed on all of our vessels, well in advance of the September 2024 deadline set by the Ballast Water Management Convention for shipowners to have treatment systems on board their vessels. Anti-fouling paints of the highest standards are applied to both reduce the hull resistance, and the risk of spreading invasive species. Höegh works actively to ensure that there are limited damages to marine life during shipping activities, in particular when navigating through marine protected areas, environmental critical areas, and areas with protected conservation status. Preventing marine casualties is one of the top priorities for our environmental performance. This involves continuous crew awareness, training regarding safety navigation and vessel stability. These two activities crucial to avoid serious marine casualties.

Port state controls

Port state control (PSC) assesses the vessels’ safety during operation including the crew’s safety. For 2023 and 2025, we have a target of zero detentions and a maximum deficiency per inspection ratio of 0.70 which is the company standard as well.

In 2023, we underwent a total of 116 port state control inspections and received a total of 75 deficiencies. This means that we had a Def/Insp ratio of 0.65, which is below the Company’s target of Def/Ins ratio of 0.7. We have also experienced one (1) detention. Nevertheless, we are seeing a generally positive downward trend in our rolling 12-month period.

This positive trend is mainly due to the effective safety barriers implemented in 2023 such as: Crew safety awareness campaigns, regular pre-PSC inspections by Class and third-party inspectors and ship visits by the vessel managers and nautical managers. The targets going forward remains to be zero PSC detentions and a Def/Insp ratio of below 0.70 .

| Year | 2023 | 2022 | 2021 |

|---|---|---|---|

| Travel days spent in marine protected areas and areas of protected conservation status | 1 741 | 1 978 | 1 978 |

| Marine casualties and zero defined as very serious marine casualties | 12 | 0 | 0 |

| PSC Inspections | 116 | 108 | 101 |

| Deficiencies | 75 | 106 | 57 |

| Detentions | 1 | 2 | 0 |

| Non-compliance of environmental laws and regulations | 0 | 0 | 0 |

| Share of fleet with ballast water treatment systems installed | 100% | 100% | 94% |

Waste

Waste from ships can include various types of materials and substances generated during the operation of a vessel, such as food waste, plastics, paper, glass, metal, oil, chemicals, and sewage. The amount and type of waste generated can vary depending on the size and type of the vessel, the duration of the voyage, and the activities carried out on board. Proper management of ship-generated waste is critical to prevent pollution and protect the marine environment.

Oil Spills

In 2023, Höegh Autoliners did not have any significant oil spills to the environment.

To continue to prevent oil spills from happening, all oil spill responses and checklists are in place in case of emergency situations. Our seafarers are equipped with adequate training and knowledge that prepares them in case of an oil spill. The target for 2024 and 2025 is zero incidents of oil spill. To achieve this goal, the following activities are conducted: enhanced crew awareness, regular PMS of the vessel and equipment maintenance (BWTS and OWS). These assure that the vessel is in good condition and performing at its best along with the best trained crews.

Waste management

It is the policy of the company to contribute to keeping the seas as clean as possible. All vessels in the fleet are following comprehensive garbage management plans, in compliance with the MARPOL guidance. The plan sets procedures for collection and storage, processing, and disposal of garbage onboard our vessels. It also ensures awareness of the crew through requirement of applicable training on proper garbage management. We have had an increased focus on garbage handling in our operations which has resulted in a lower amount of waste generated in 2023 compared to 2022. Generated waste on board the vessels are separated in containers in accordance with our policy and continuously practice a zero waste overboard principle, including waste disposal/recycling at approved shore facilities in ports.

Our targets for waste management in 2024 is to have newbuildings delivered with 100% LED lights onboard and a reduction of 5% plastic generation compared to prior year’s levels

| Breakdown of wastes in m3 | 2023 | 2022 | 2021 |

|---|---|---|---|

| Plastics | 714 | 682 | 693 |

| Aerosol cans | 2 | 1 | 6 |

| Bilge water | 5 052 | 6 005 | 5 911 |

| Carbon soot from economizer | 5.34 | 4 | 1 |

| Domestic waste | 433 | 434 | 435 |

| Expired pyrotechnics | 2 | 1 | 3 |

| Incinerator ash | 25 | 26 | 24 |

| Operational waste | 274 | 216 | 217 |

| Used batteries | 3 | 1 | 34 |

| Sludge / waste oil | 5 591 | 6 043 | 5 840 |

| Cooking oil | 69 | 6 | 59 |

| Food waste | 149 | 170 | 173 |

| Scrap iron from ER | 17 | 24 | 23 |

| Fluorescent lamp | 19 500 pcs | 24 194 pcs | 17 540 pcs |

| Hazardous (except fluorescent lamps) | 12 336 (98%) | 13 613 (99%) | 13 323 (98%) |

| Non-hazardous | 254 (2%) | 201 (1%) | 255 (2%) |

| Total waste generated (m3) | 12 590 | 13 814 | 13 578 |

Green Ship Recycling

Resource use and circular economy principles are becoming increasingly important, with a focus on reducing waste and promoting the reuse and recycling of materials, including through responsible ship recycling practices, creating opportunities for companies that invest in sustainable practices and contributing to the protection and conservation of natural resources.

Ship recycling may have material impacts on the environment and society, including pollution, workers safety concerns, and resource depletion. Responsible practices are crucial to safeguard human health, the environment, and circular economy principles that minimise waste and encourage material reuse and recycling. It is expected that it will be an increased demand for ship recycling in the coming decade, as deliveries of newbuildings together with stricter environmental regulations will push owners to recycle older vessels earlier than planned. As part of our decarbonisation journey, we will phase out legacy tonnage at the end of the vessels’ lifetime, which most likely will include ship recycling in the short term.

Höegh Autoliners have adopted responsible ship recycling practices, such as those outlined in the Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships, to reduce the social and environmental impact. This means that we are executing disposals of old vessels in a manner that is safe to both people and the environment, including obsolete vessells declared as total losses. Vessels are dismantled under strict requirements in approved shipyard facilities. Any recycling yard selected must comply with Höegh Autoliners Supplier Code of Conduct.

In working with qualified ship recycling facilities, they need to have established management systems, procedures, and techniques that do not pose health risks to workers or have a negative impact on a local community. By choosing established ship recyclers who have facilities that handle toxic waste responsibly and ensure proper safety procedures that protect workers, Höegh Autoliners maintains its strict safety standards when recycling vessels. It is also required by our Green Recycling Standard that any recycle facility should only use fully licensed and permitted facilities for downstream waste management

Since committing its first vessel to green recycling in 2009, the Group has only disposed ships through green recycling.

In 2023, Höegh Autoliners did not recycle any vessels.

People

At Höegh Autoliners, success stems from our dedicated people. Celebrated for their talent, diversity, and passion, they are the driving force behind our achievements. Every team member, from leadership to frontline, is key to our continued innovation and development to be a frontrunner in the industry.